By Llewellyn King

If you want to design a new automobile, there are choices, but there are also parameters. For example, you would be advised to start with four wheels on the ground. You could design it with three, but the trade-offs are considerable.

When it comes to designing a new nuclear reactor for generating electricity, there are no such absolutes. A nuclear reactor only needs a safe nuclear reaction and the ability to harness the resulting heat. That means that nuclear reactors can be configured in all kinds of ways with considerable variety in the design of the fuel, the size of the reactor, the cooling system and the moderator (usually water).

Not only can the configuration of the fuel vary with differing results, but the fuel also can vary. It can be, for example, the intriguing metal thorium, which is plentiful in nature. It is fertile but not fissile, which means it takes uranium or plutonium to get a nuclear reaction going. When that happens, a thorium reactor appears to have advantages, from the availability of the fuel to the safety of the reactor.

Yet most of the world’s commercial civilian reactors – more than 400 — have just one basic design: uranium-fueled light water. The moderator is water.

Adm. Hyman G. Rickover, the father of the nuclear Navy, favored this technology. Recognizing that left to their own devices, nuclear engineers would come up with dozens of reactors, and would stymie the effort get industry off the ground, Rickover pushed light water. The admiral was a man who got what he wanted. So the light water reactor (LWR) became the world standard with some national exceptions.

Canada developed a very successful reactor that uses natural uranium, but requires heavy water: water with an extra hydrogen atom. Britain built two different reactor designs, the Magnox and the Advanced Gas Reactor, but finally has come around to the light water reactor. The Soviet Union went ahead with its own designs, including the disastrous Chernobyl design.

Although LWR construction steams ahead in China, and more hesitatingly elsewhere, there is a sense that it is time for change. Time to look at other designs and fuels.

In the United States, the Department of Energy has stimulated interest in a new generation of small modular reactorsand some ideas, which got pushed aside by light water technology, are doggedly holding on and even fighting back. Among these are various gas reactor concepts and fast reactors, where the neutron flux is not slowed down and which can do amazing things, including burning a certain proportion of nuclear waste.

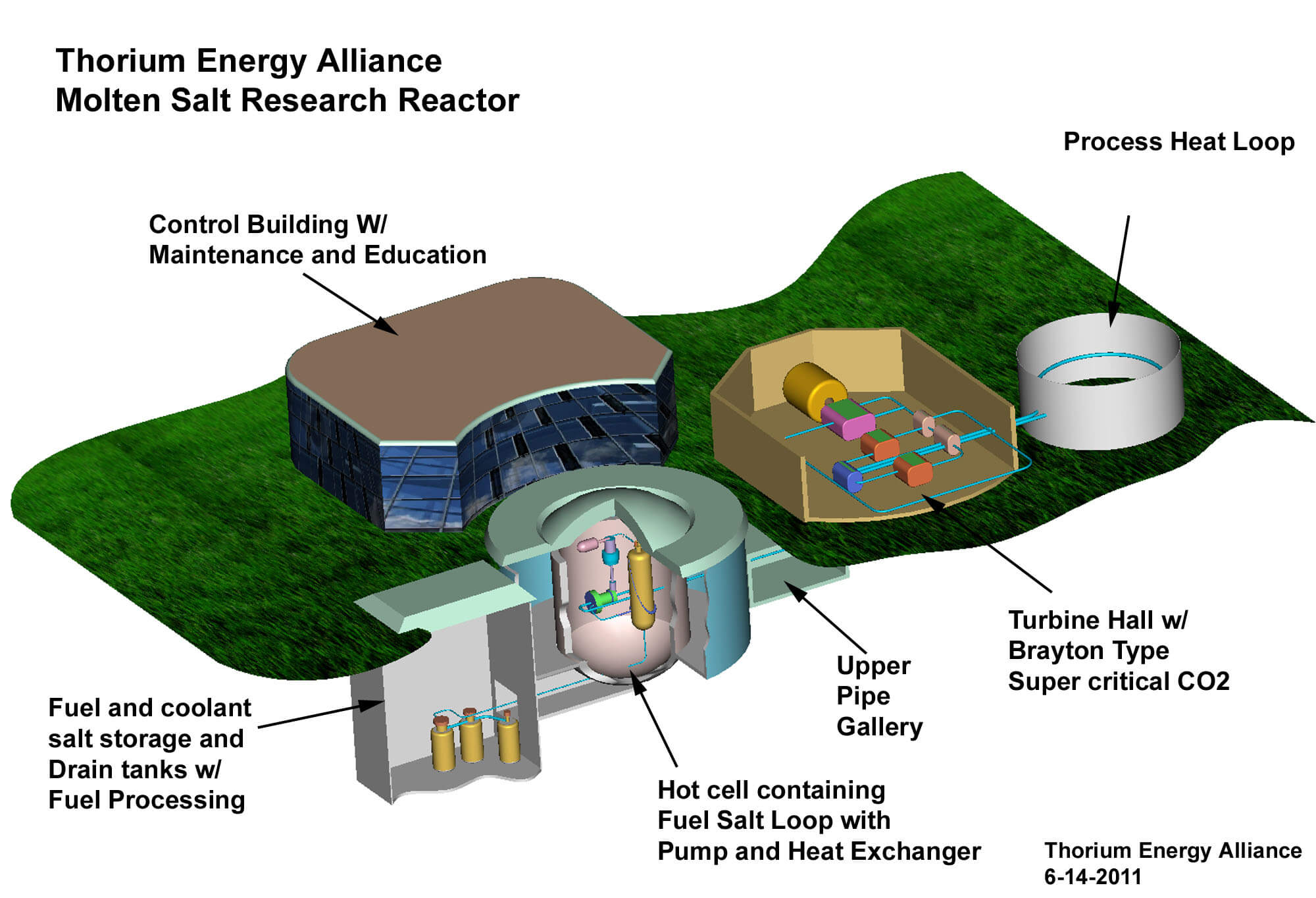

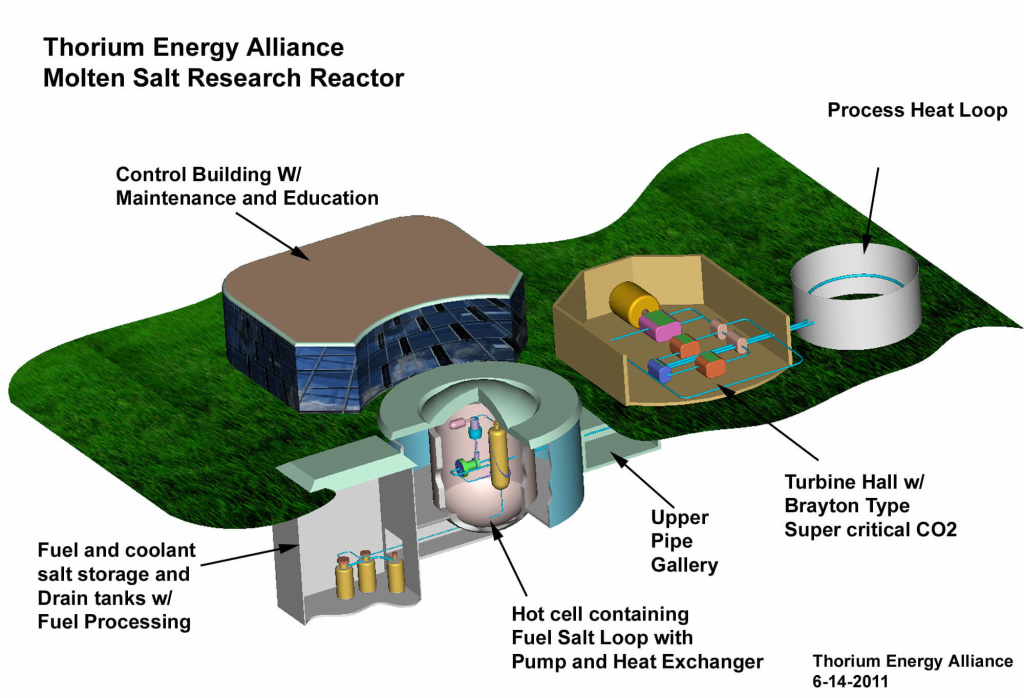

The molten salt thorium reactor continues to have its advocates, although this technology is not included in DOE’s small modular reactor program. It is not a new idea, but it is one that has been given short shrift from the nuclear establishment in recent years. Promising work on it was done at the Oak Ridge National Laboratory in Tennessee in the 1960s, under the legendary scientist and laboratory director Alvin Weinberg. He died in 2006, and I was lucky to have known him.

When I attended the Thorium Energy Alliance annual conference, held in Palo Alto, Calif., this year, I felt I had stumbled into an old-fashioned revival meeting. They are believers. Work on thorium-fueled reactors is ongoing in China, India and Russia.

But the best hope for thorium future may not lie in the nuclear sphere at all. It may rest with rare earths, and the global appetite for these in a high-tech world. A simple way to understand rare earths is that in technology they are great multipliers, making products in consumer electronics, computers and networks, communications, electricity generation, health care, advanced transportation, and across a wide range of defense materiel, more effective. With a small application, say to the turbine in a wind generator, the efficiency may increase several times.

Rare earths — which are not really rare at all — are found in conjunction with thorium, often in phosphate mining. When the world gets serious about the rare earths supply, it has to get serious about thorium, especially in the United States.The Thorium Energy Alliance would like to see thorium put into a national stockpile, so that it is available when the pendulum in reactor design swings to thorium, and that becomes the future.

Can the 17 rare earth elements become the thorium reactor’s enabler? Some devoutly believe so. — For the InsideSources news service.